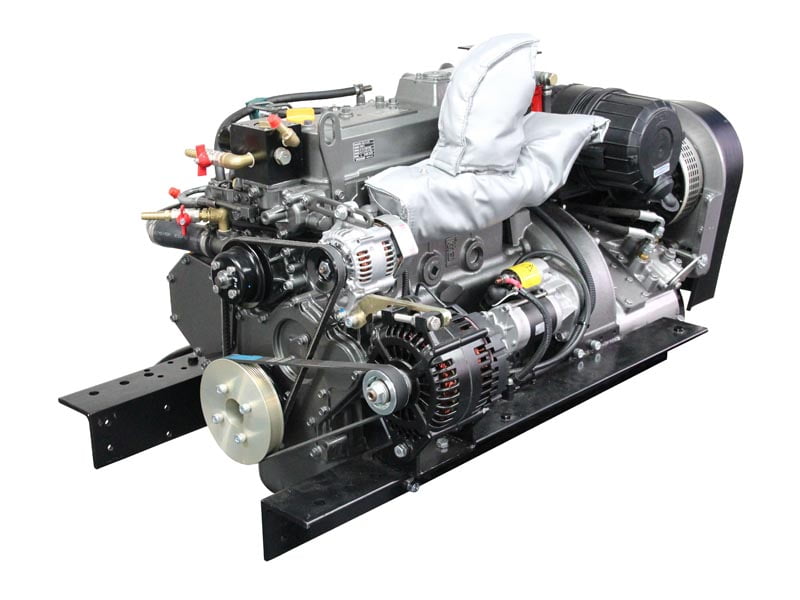

Hybrid Marine Ltd and Barrus have been working together since 2008 which resulted in the first Parallel Hybrid Saildrive system based on the Yanmar marine diesel engine range.

There was little early reaction from boat builders, but with the familiarity of hybrid cars, there came a rapidly increasing interest in Hybrid installation amongst boat owners.

A parallel hybrid system can be fitted to a vessel during its initial construction or retrofitted to an existing diesel installation. Suitable for vessels up to 50 feet this approach brings key advantages including built-in redundancy should either the diesel engine or the electric drive fail.

Based on Yanmar engines from 30hp to 110hp, the system offers many advantages including improved fuel consumption and an extended cruising range on limited fuel resources. Controlled by innovative electronic technology, the complexity is hidden away, and a user-friendly control panel provides simple system operation. Additional functionality allows the system to be used a standalone diesel generator even when the vessel is stationary, eliminating the need to purchase a separate, expensive and heavy diesel generator.

How does the parallel hybrid work?

During low to mid power cruising (around two-thirds of the maximum hull speed), the electric motor can drive the vessel using the energy stored in the battery bank. When the batteries are depleted, the main engine is started to propel the craft. The electric motor automatically becomes a generator and recharges the batteries. The extra shaft load seen by the engine during this combined propulsion and charging period causes the engine to operate with higher efficiency. Once the batteries are recharged you can switch back to electric drive. Alternatively, the energy can be kept in the batteries to silently drive high power appliances when anchored at the end of the day.

If there is a need to punch into heavy sea, or motor against the tide, the hybrid will back off the generator so the full power of the diesel engine can be used to drive the propeller. In calmer conditions, you can slip your lines and motor in complete silence under electric drive.

The need to work closely with boat builders to design hybrids that meet their individual requirements is very important. Implementing a hybrid is not as simple as fitting another engine. The entire craft must be taken into account, and, in some cases, the boat itself is designed around the hybrid system. “This requires a strong commitment to hybrids from the builder and a close working relationship with the hybrid supplier through the design and prototyping process. We understand very well that one size does not fit all and we work closely with builders to design hybrids to meet individual requirements,” comments Graeme Hawksley, Managing Director, Hybrid Marine Ltd.

A hybrid system based on a Yanmar 4JH57 common rail engine with a 10kW electric motor will be showcased at Seawork.